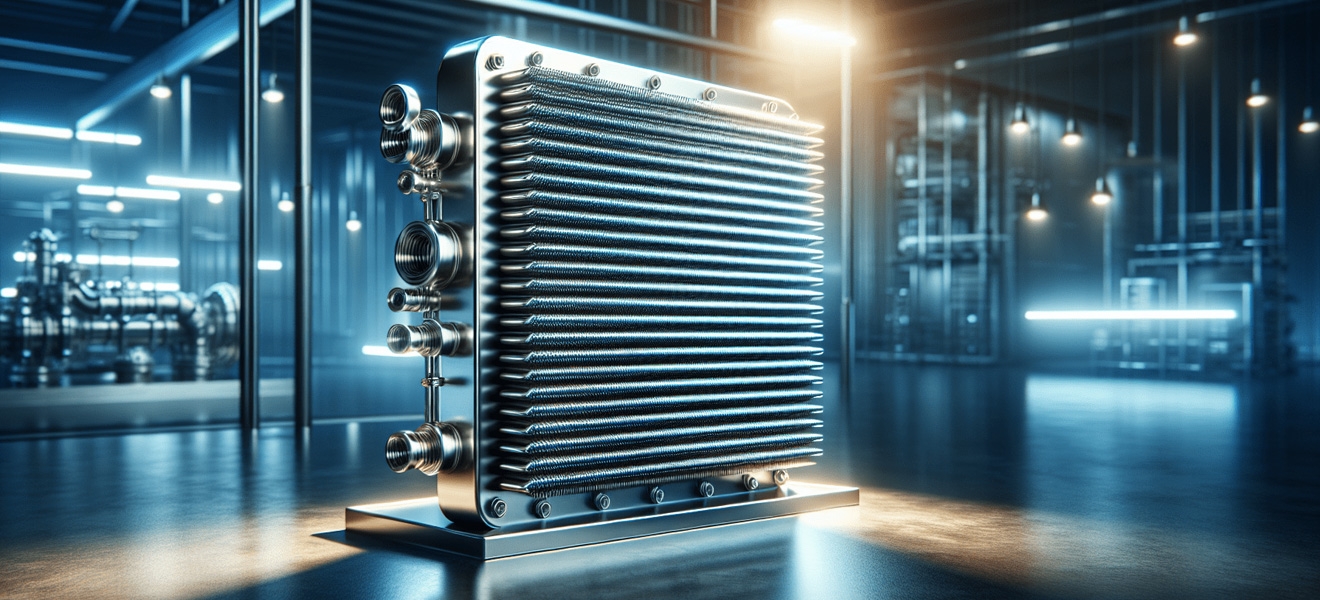

Stainless Steel for Heat Exchanger Construction

When selecting stainless steel (SS) for the construction of heat exchangers, it is essential to first examine the different categories of these steels. Stainless steels are alloys that contain at least 12% chromium, with or without other alloying elements.

Compared to plain carbon steels and low-alloy steels, stainless steels are significantly more resistant to rust and corrosion, primarily due to their high chromium content. These metals are available in both wrought and cast forms, and they can be classified into five families based on their metallurgical structure:

- 1. Martensitic Stainless Steel

- 2. Austenitic Stainless Steel

- 3. Ferritic Stainless Steel

- 4. Duplex Stainless Steel

- 5. Precipitation Hardening Stainless Steel

The first four categories are distinguished by their metallurgical phases. In iron and steel, ferrite has a body-centered cubic (BCC) structure, while austenite has a face-centered cubic (FCC) structure. Thus, ferritic and austenitic steels contain significant amounts of these phases, respectively. Duplex stainless steels contain a mix of both ferrite and austenite phases. Precipitation hardening stainless steels, the fifth category, are strengthened through aging heat treatment, but they are not typically used in heat exchanger applications and therefore will not be discussed further in this article.

Nomenclature of Stainless Steels

Wrought stainless steels are classified based on the American Iron and Steel Institute (AISI) standards, which group them by their chemical composition. For example, austenitic stainless steels are categorized under the 200 and 300 series. The Cr-Ni-Mn (Chromium-Nickel-Manganese) series is identified as the 200 series, while the Cr-Ni (Chromium-Nickel) series is grouped under the 300 series. Precipitation-hardening grades are categorized based on their nickel and chromium content. The most common designation system is based on AISI and ASTM specifications, where stainless steels are identified by specific letters (such as A for austenitic, F for ferritic, M for martensitic) and a number indicating the alloy family.

Guidelines for Selecting Stainless Steels

Brown and Diebold have extensively studied the selection of appropriate stainless steel grades for various applications. According to Brown, several factors must be considered when selecting the right grade:

- 1. Corrosion resistance requirements for the intended application.

- 2. Strength requirements.

- 3. The base alloy’s properties to ensure optimal performance during manufacturing processes.

- 4. A cost analysis that considers material costs, installation expenses, and the estimated lifespan of the final product.

- 5. Availability of raw materials that offer a balance between cost and performance.

Diebold also emphasizes the importance of balancing corrosion resistance and mechanical strength when selecting stainless steels for heat exchangers.

Martensitic Stainless Steels

Martensitic stainless steels offer lower corrosion resistance because they contain 11 to 18% chromium and typically less than 0.4% carbon. The minimum chromium content is chosen for corrosion resistance, while the maximum amount is based on the need to fully austenitize the alloy during heat treatment. A key feature of this group is its ability to be hardened through heat treatment, making it particularly useful in applications where a combination of strength, ductility, toughness, and mild corrosion resistance is required.

Martensitic steels are limited in their use in heat exchangers, especially in aqueous environments. However, they can perform well in mild environments when fully hardened and tempered. One of the most commonly used martensitic grades in heat exchangers is AISI 410.

Austenitic Stainless Steels

Austenitic stainless steels account for 80 to 90% of all stainless steels. This family includes alloys from the 200 and 300 series, which can be hardened by cold working. The 200 series was developed to reduce nickel content by substituting it with manganese, typically using a 2:1 ratio of manganese to nickel. The 300 series are low-carbon iron-chromium-nickel alloys that can contain small amounts of manganese or nitrogen. These alloys are non-magnetic, ductile, and formable, and they maintain an austenitic structure at room temperature when rapidly cooled.

Chromium content in austenitic steels typically ranges from 15% to 32%, while nickel content is between 8% and 37%. Carbon content is kept below 0.03% to maintain corrosion resistance. Chromium provides oxidation resistance, while nickel enhances corrosion resistance in reducing environments. Common austenitic grades include 304, 304L, 316, and 316L. Type 304, the most widely used alloy, contains 18% chromium and 8% nickel, offering moderate strength, excellent corrosion resistance, and outstanding toughness. For applications in chloride-rich environments, molybdenum is added to improve resistance to pitting corrosion, as in grades 316 and 317.

Alloy Development for Heat Exchangers

Austenitic stainless steels, such as Cr–8Ni alloys, have been successfully used in freshwater and mildly corrosive industrial environments for over 50 years. Their corrosion resistance, weldability, and strength make them ideal for various heat exchanger applications. Key developments in alloy composition include:

- 1. The addition of molybdenum to enhance resistance to chloride-induced corrosion, as seen in grades 316 and 317.

- 2. The use of low-carbon grades (e.g., 304L, 316L) to prevent carbide precipitation during welding, ensuring corrosion resistance remains intact in the heat-affected zone.

- 3. Nitrogen is added to increase strength and improve resistance to localized corrosion in chloride environments.

- 4. Increased chromium content for enhanced resistance to pitting and crevice corrosion.

- 5. Nickel stabilizes the austenitic microstructure and improves resistance to stress corrosion cracking in aggressive environments.

- 6. The addition of titanium or niobium to stabilize the microstructure and prevent chromium carbide formation, as seen in grades 321 and 347.

In conclusion, selecting the appropriate stainless steel for heat exchangers requires a careful balance of corrosion resistance, mechanical properties, and cost-effectiveness. Advances in alloy development have further improved the performance of stainless steels in a wide range of industrial applications.